Products

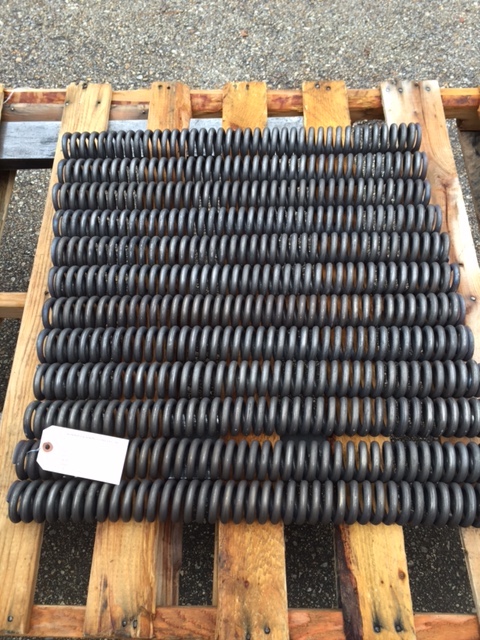

Compression Springs

Compression springs are an open coiled spring that becomes shorter when a force is applied to it.

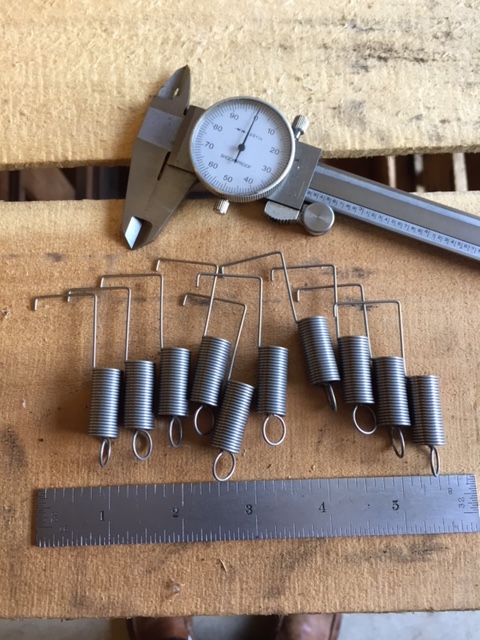

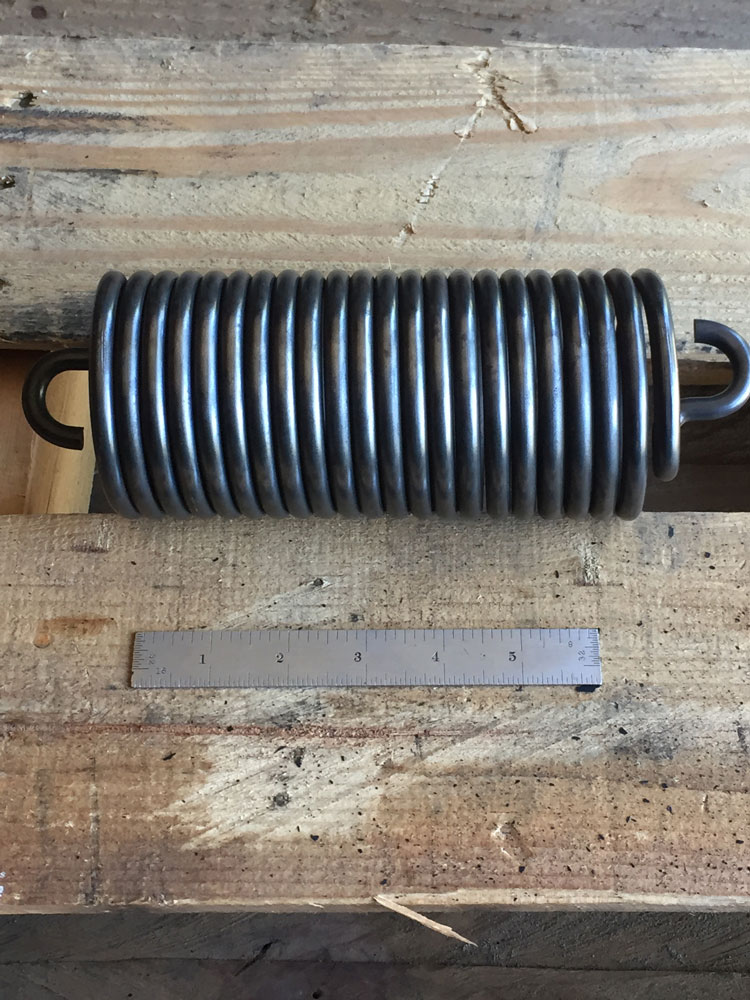

Extension Springs

Extension springs are close wound helical springs with a variety of hooks/loops on the ends. They extend from original length when a force is applied.

Torsion Springs

Torsion Springs are a single set of coils with legs or ends that rotate/twist (torque) when a force is applied.

Power Springs

& Brush Holder Springs

Power springs (also known as Recoil springs or Motor springs) store and release rotational energy in the form of torque.

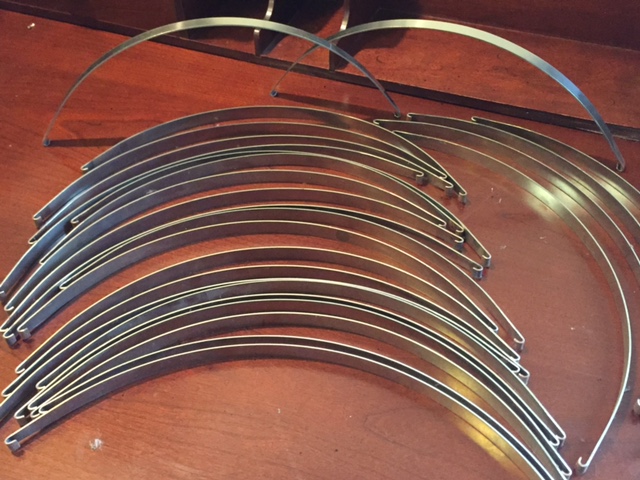

Flat Springs

Flat springs are manufactured for a variety of uses. The width, thickness and type of material used comes in a large assortment.

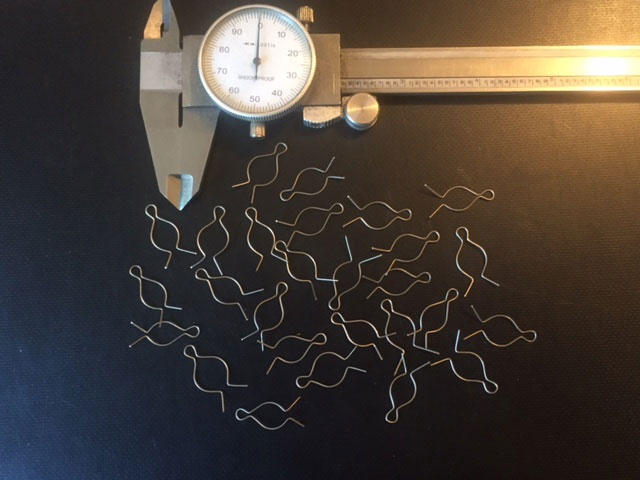

Wire Forms

Flat springs are manufactured for a variety of uses. The width, thickness and type of material used comes in a large assortment.